Product Description

Product Description

Quick details

Gland —-High grade ductile iron

Tube —–Cold drawn honed tubling

Piston—–High grade ductile iron

Piston rod—-Chromed C45

Piston seal—-Urethane seal

End cap—-Casting seel

Mounting style—-Pins and clips included

Gland seals—-Polyurethane U-cup

Rod wiper—-Urethane snap in

Paint color—-Semi-gloss black, grey, red

1.Light-weight,high strength

Base on the nature of construction work,the hydraulic cylinders need to suit for high strength,high

using frequency,high fatigability.to promise the sability and reliablity of application.

2.the seal system

select the excellent seal kits from japan and germany.adopt the advanced physical design,make

sure the hydraulic cylinder get the best piston rod oil film

3.cylinder body

adopt the good-quality alloy honed tube,though cold-drawing and rolling,to reach an excellent

toughness and surface hardness.improve the wear-resistance.

4.piston rod

middle frequency induction hardening and tempering,chrome plated on rod surface to improve the

anti-rust ,wear-resistance and anti-scratch property.

5.safety/cushioning fuction

The inside of cylinder set up an cushioning device in the end of stroke,it can absorb the juge inpact.

Technical Specification size.

|

cylinder diameter (mm) |

piston rod diameter (mm) |

max stroke (mm) |

||

|

40 |

20 |

22 |

25 |

500 |

|

50 |

25 |

28 |

32 |

600 |

|

63 |

32 |

35 |

45 |

800 |

|

80 |

40 |

45 |

55 |

2000 |

|

90 |

45 |

50 |

63 |

2000 |

|

100 |

50 |

55 |

70 |

4000 |

|

110 |

55 |

63 |

80 |

4000 |

|

125 |

63 |

70 |

90 |

4000 |

|

140 |

70 |

80 |

100 |

4000 |

|

150 |

75 |

85 |

105 |

4000 |

|

160 |

80 |

90 |

110 |

4000 |

|

180 |

90 |

100 |

125 |

4000 |

|

200 |

100 |

110 |

140 |

4000 |

|

220 |

110 |

125 |

160 |

4000 |

|

250 |

125 |

140 |

180 |

4000 |

Cylinder tube machining

Piston

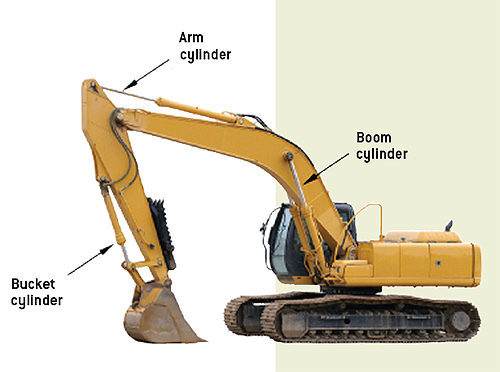

Application boom cylider, stick cylinder, Dozer cylinder.

| Excavator Type | Name | Stroke (mm) | Installation Diameter(mm) | Cylinder Diameter(mm) | Rod Diameter(mm) |

| 5.5T | Boom Cylinder | 710 | 1120 | 115 | 65 |

| Stick Cylinder | 815 | 1210 | 90 | 55 | |

| Bucket Cylinder | 605 | 945 | 85 | 55 | |

| Dozer Cylinder | 150 | 500 | 110 | 60 | |

| 6.5T | Boom Cylinder | 885 | 1311 | 110 | 65 |

| Stick Cylinder | 900 | 1300 | 90 | 60 | |

| Bucket Cylinder | 730 | 1120 | 80 | 50 | |

| Dozer Cylinder | 145 | 565 | 130 | 70 | |

| 11.5T | Left Boom Cylinder | 980 | 1480 | 100 | 70 |

| Right Boom Cylinder | 980 | 1480 | 100 | 70 | |

| Stick Cylinder | 1571 | 1530 | 115 | 80 | |

| Bucket Cylinder | 885 | 1375 | 95 | 65 | |

| 18.5T | Left Boom Cylinder | 1195 | 1790 | 120 | 85 |

| Right Boom Cylinder | 1195 | 1790 | 120 | 85 | |

| Stick Cylinder | 1405 | 2000 | 130 | 95 | |

| Bucket Cylinder | 1110 | 1630 | 110 | 80 | |

| 20T | Boom Cylinder | 1285 | 1870 | 120 | 85 |

| Stick Cylinder | 1490 | 2075 | 135 | 95 | |

| Bucket Cylinder | 1120 | 1680 | 115 | 80 | |

| 23T | Boom Cylinder Assembly | 1295 | 1870 | 130 | 90 |

| Stick Cylinder Assembly | 1675 | 2225 | 140 | 100 | |

| Bucket Cylinder Assembly | 1156 | 1744 | 130 | 90 | |

| 26T | Boom Cylinder Assembly | 1420 | 1980 | 139 | 100 |

| Stick Cylinder Assembly | 1748 | 2348 | 149 | 110 | |

| Bucket Cylinder Assembly | 1130 | 1753 | 134 | 100 | |

| 40T | Boom Cylinder Assembly | 1495 | 2135 | 160 | 110 |

| Stick Cylinder Assembly | 1790 | 2480 | 170 | 110 | |

| Bucket Cylinder Assembly | 1285 | 1990 | 160 | 110 |

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment 30%TT in advance. 70% T/T before shippment

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Single Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Switching Type |

| Samples: |

US$ 120/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can boom cylinders be repaired or replaced when damaged?

Yes, boom cylinders can be repaired or replaced when damaged. Here’s a detailed explanation:

Boom cylinders, like any other mechanical component, can experience damage or wear over time due to various factors such as heavy use, environmental conditions, or accidents. However, they can often be repaired or replaced to restore functionality and extend the lifespan of the machinery. Here are the options for addressing damaged boom cylinders:

- Repair: Depending on the extent of the damage and the specific issue, certain components of a boom cylinder can be repaired. Common repairs may include fixing leaks, replacing damaged seals or gaskets, repairing or replacing damaged rods, or reconditioning the cylinder’s body. These repairs are typically performed by skilled technicians or hydraulic specialists who have expertise in boom cylinder repair.

- Replacement of Components: In some cases, specific components of a boom cylinder may need to be replaced. This could include replacing damaged rods, piston heads, seals, or other internal parts. By replacing the damaged components, the cylinder can be restored to proper working condition. It’s important to use high-quality replacement parts that meet the manufacturer’s specifications to ensure compatibility and performance.

- Complete Cylinder Replacement: If the damage to the boom cylinder is extensive or if repair is not feasible, a complete cylinder replacement may be necessary. In such cases, the damaged cylinder is removed from the machinery, and a new or refurbished cylinder is installed. Complete cylinder replacements are typically carried out by authorized service centers or dealerships to ensure proper installation and compatibility with the machinery.

The decision to repair or replace a boom cylinder depends on factors such as the extent of the damage, cost-effectiveness, availability of replacement parts, and the overall condition of the machinery. It is recommended to consult with qualified technicians or professionals who have expertise in hydraulic systems to assess the damage and provide appropriate recommendations.

Regular maintenance and inspections can help detect potential issues with boom cylinders early on, allowing for timely repairs and minimizing downtime. Following the manufacturer’s recommended maintenance schedule and implementing proper operating practices can also contribute to the longevity and reliability of boom cylinders.

How does a boom cylinder contribute to load distribution and control?

A boom cylinder plays a significant role in load distribution and control. Here’s a detailed explanation:

In various applications such as construction equipment, material handling machinery, and mobile cranes, boom cylinders are responsible for supporting and controlling the load. They help distribute the load forces and provide precise control over the movement of the boom or arm. Here’s how a boom cylinder contributes to load distribution and control:

- Load Support: Boom cylinders are designed to withstand and support the loads encountered during operation. They are typically mounted between the machine’s main body and the boom structure, providing a connection that carries the weight and forces of the load. The cylinder’s robust construction and load-bearing capacity ensure that the load is evenly distributed and properly supported.

- Force Generation: Boom cylinders generate the required force to control the movement of the boom or arm. By extending or retracting, the cylinder exerts force on the boom, allowing it to lift, lower, swing, or articulate as needed. The cylinder’s ability to generate and regulate force ensures precise load control, contributing to safe and efficient operation.

- Load Stabilization: Boom cylinders help stabilize the load during lifting or movement. By resisting undesired movements or vibrations, the cylinder assists in maintaining the load’s stability and preventing excessive swinging, tilting, or shifting. The controlled movement provided by the cylinder helps minimize the risk of load damage or accidents, ensuring safer and more controlled operations.

- Balance and Alignment: Boom cylinders aid in achieving balance and alignment of the load. By controlling the extension or retraction of the boom, they allow operators to adjust the position of the load relative to the machine’s center of gravity. This balancing capability helps optimize stability, prevent tipping, and enable precise positioning of the load.

- Controlled Speed: Boom cylinders enable precise control over the speed of load movement. By regulating the extension or retraction speed, the cylinder allows operators to adjust the lifting or lowering speed according to the requirements of the task. This controlled speed enhances load handling precision, minimizes impact forces, and improves overall safety.

The use of a boom cylinder in load distribution and control offers several benefits:

- Enhanced Safety: Boom cylinders contribute to load stabilization, balance, and controlled movement, reducing the risk of load accidents or instability.

- Precise Load Handling: The force generation and controlled speed provided by boom cylinders enable operators to handle loads with precision, ensuring accurate placement and minimizing the potential for damage.

- Improved Efficiency: Boom cylinders facilitate efficient load distribution and control, enhancing productivity and reducing the time required to complete tasks.

- Load Capacity Optimization: By supporting and distributing the load forces, boom cylinders help optimize the machine’s load capacity and performance.

Overall, a boom cylinder is a crucial component in load distribution and control. It provides load support, generates force, stabilizes the load, aids in balance and alignment, and enables controlled speed. These features contribute to safe, precise, and efficient load handling in various applications.

It’s important to follow the manufacturer’s guidelines and recommendations regarding the selection, installation, and maintenance of boom cylinders to ensure their proper functioning and optimal load control.

Can you explain the role of hydraulic fluid in a boom cylinder?

Hydraulic fluid plays a crucial role in the operation of a boom cylinder in heavy machinery. Here’s a detailed explanation of its role:

- Transmission of Power: Hydraulic fluid is the medium through which power is transmitted in a boom cylinder. When hydraulic fluid is supplied under pressure to one side of the cylinder, it exerts force on the piston, causing it to move. This movement is then transferred to the boom, enabling its extension, retraction, lifting, or lowering. The ability of hydraulic fluid to transmit power efficiently allows for smooth and controlled operation of the boom cylinder.

- Force Generation: Hydraulic fluid is responsible for generating the force required to move the boom. The pressure applied to the hydraulic fluid creates a force that acts on the piston, creating a pushing or pulling action. This force is then transmitted to the boom through the piston and rod, allowing for the desired movement. The force generated by the hydraulic fluid depends on the pressure applied and the effective area of the piston.

- Control of Movement: Hydraulic fluid enables precise control of the boom cylinder’s movement. By regulating the flow and pressure of the hydraulic fluid, operators can control the speed, direction, and extent of the boom’s extension, retraction, lifting, or lowering. This control allows for accurate positioning of the boom, precise load handling, and safe operation of the heavy machinery.

- Heat Dissipation: Hydraulic fluid also plays a role in dissipating heat generated during the operation of the boom cylinder. As hydraulic fluid flows through the system, it absorbs heat from the hydraulic components and transfers it to the reservoir or other heat dissipation mechanisms. Adequate heat dissipation prevents the hydraulic fluid from overheating, which could lead to a loss of performance or damage to the components.

- Lubrication and Seal Protection: Hydraulic fluid provides lubrication to the moving components within the boom cylinder, such as the piston, rod, and seals. This lubrication minimizes friction and wear, ensuring smooth and efficient operation of the cylinder. Additionally, hydraulic fluid helps protect the seals from drying out or being damaged by contaminants, maintaining the integrity of the cylinder and preventing fluid leakage.

- System Stability and Safety: The proper selection and maintenance of hydraulic fluid contribute to the stability and safety of the boom cylinder system. Using the recommended hydraulic fluid with the appropriate viscosity and additives ensures optimal performance and protects the system from wear, corrosion, and fluid breakdown. Regular monitoring and maintenance of the hydraulic fluid help identify potential issues, such as contamination or degradation, and prevent system failures or malfunctions.

In summary, hydraulic fluid plays a vital role in a boom cylinder by transmitting power, generating force, controlling movement, dissipating heat, providing lubrication and seal protection, and contributing to system stability and safety. Its properties and effective utilization are essential for the efficient and reliable operation of the boom cylinder in heavy machinery.

editor by CX 2023-11-27