Product Description

| long stroke telescopic hydraulic cylinders | |||

| Part number | Tube dia mm | Rod dia mm | Stroke mm |

| 205-63-57100 | 120 | 85 | 1285 |

| 206-63-57100 | 120 | 85 | 1285 |

| 205-63-57160 | 120 | 85 | 1285 |

| 205-63-57120 | 135 | 95 | 1490 |

| 203-63-57130 | 125 | 85 | 1120 |

| 203-63-57131 | 125 | 85 | 1120 |

| 205-63-57130 | 125 | 85 | 1120 |

Specifications

1.Supply to USA,Europe,and Australia, Russia.

2.Material:Stainless Steel

3.Professional performance excavator parts supplier

4. High quality and low price

FAQ

Q1: Are you Manufacture or Trade Company?

A1: We are manufacture,we have 20 years experience for supply Metal material and products in domestic.

Q2: How can we guarantee quality?

A2: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q3: What is your terms of payment ?

A3: 1.T/T: 30% deposit in advance, the balance 70% paid before shipment

2.30% down payment, the balance 70% paid against L/C at sight

3.CHINAMFG negotiation

Q4: Can you provide Certificates for aluminum materials ?

A4:Yes,we can supply MTC-Material Test Certificate.

Q5: Can you provide sample?

A5: Yes, we can provide you sample, but you need to pay for the sample and freight firstly. We will return the sample fee after

you make an order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Piston Cylinder |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

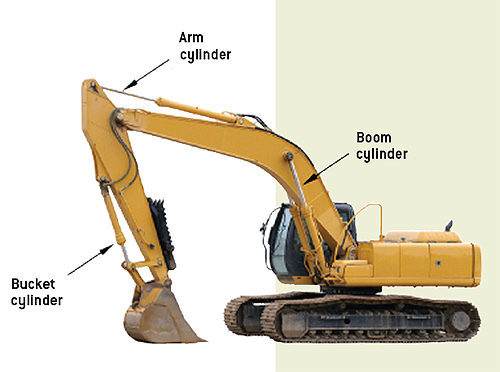

How does a boom cylinder handle variations in load capacity and weight?

A boom cylinder is designed to handle variations in load capacity and weight in heavy machinery. Here’s a detailed explanation:

When a machinery equipped with a boom cylinder is used for different tasks, the load capacity and weight requirements may vary. The boom cylinder is designed to accommodate these variations and ensure optimal performance. Here are the key factors that contribute to how a boom cylinder handles load capacity and weight variations:

- Force Generation: The boom cylinder generates the necessary force to move the boom, arm, or attachment of the machinery. The force generated by the cylinder can be adjusted based on the load capacity and weight requirements. By controlling the hydraulic pressure and flow rate, the operator can regulate the force exerted by the cylinder, allowing it to handle both lighter and heavier loads.

- Adjustable Stroke Length: Boom cylinders often have an adjustable stroke length, which is the distance the piston can travel within the cylinder. By adjusting the stroke length, the cylinder can adapt to different load capacities and weight distributions. For heavier loads, a longer stroke may be required to provide the necessary extension or retraction of the boom. Conversely, for lighter loads, a shorter stroke may be sufficient, optimizing the cylinder’s efficiency.

- Pressure Compensation: Some boom cylinders are equipped with pressure compensation mechanisms. These mechanisms automatically adjust the hydraulic pressure within the cylinder to compensate for variations in load capacity and weight. For example, as the load on the boom increases, the pressure compensation mechanism increases the hydraulic pressure, ensuring consistent force and control throughout the operation.

- Integration with Load Sensing Systems: Boom cylinders can be integrated with load sensing systems that provide real-time feedback on the load capacity and weight. Load sensing systems use sensors to measure the force exerted on the boom or attachment and transmit this information to the hydraulic control system. The hydraulic control system can then adjust the pressure and flow rate to match the load requirements, optimizing the cylinder’s performance.

- Multi-Stage Cylinders: In some cases, machinery may be equipped with multi-stage boom cylinders. These cylinders have multiple sections or stages that can be extended or retracted independently. Each stage may have different dimensions and force capabilities. By adjusting the extension or retraction of each stage, the cylinder can adapt to varying load capacities and weight distributions, providing precise control and handling.

By incorporating these design features and mechanisms, a boom cylinder can effectively handle variations in load capacity and weight. This allows the machinery to perform a wide range of tasks with different load requirements, providing versatility and efficiency in industries such as construction, mining, material handling, and more.

How does a boom cylinder handle variations in cylinder mounting and orientation?

A boom cylinder is designed to handle variations in cylinder mounting and orientation. Here’s a detailed explanation:

In different applications, such as construction equipment, material handling machinery, or hydraulic systems, boom cylinders may need to accommodate variations in cylinder mounting and orientation. The design and features of a boom cylinder allow it to adapt to these variations and function effectively. Here’s how a boom cylinder handles variations in cylinder mounting and orientation:

- Flexible Mounting Options: Boom cylinders are designed with flexible mounting options to accommodate different equipment configurations. They can be mounted in various orientations, such as vertically, horizontally, or at an angle, depending on the specific requirements of the application. The cylinder’s mounting flexibility allows for easy integration into different systems and ensures proper alignment and connection between the boom and the equipment.

- Articulating Capability: Boom cylinders often have articulating capability, which enables them to handle variations in cylinder orientation. The cylinder may have multiple pivot points or joints, allowing it to articulate and adjust its angle or position relative to the boom or equipment. This articulation capability ensures that the cylinder can adapt to different mounting angles and orientations, providing optimal performance and load control.

- Rotational Movement: Some boom cylinders are designed to handle rotational movement. They can rotate or swivel around their mounting points, allowing them to accommodate variations in cylinder orientation. This rotational movement ensures that the cylinder can align with the desired direction of force or movement, regardless of the mounting angle or orientation.

- Flexible Hydraulic Connections: Boom cylinders have flexible hydraulic connections to accommodate variations in cylinder mounting and orientation. The hydraulic hoses or fittings are designed to be adjustable or swivel, allowing for easy connection to the hydraulic system of the equipment. This flexibility ensures that the hydraulic fluid can flow smoothly and reach the cylinder, regardless of its mounting position or orientation.

The ability of a boom cylinder to handle variations in cylinder mounting and orientation offers several benefits:

- Versatility: Boom cylinders can be used in a wide range of equipment configurations and applications, providing versatility and adaptability.

- Optimal Performance: The flexibility in mounting and orientation allows boom cylinders to achieve optimal performance and load control in different working conditions.

- Easy Integration: The flexible mounting options and hydraulic connections simplify the integration of boom cylinders into various systems, reducing installation time and effort.

- Improved Efficiency: Boom cylinders that can handle variations in mounting and orientation contribute to efficient operation, as they can be adjusted to suit specific requirements and constraints.

Overall, a boom cylinder is designed to handle variations in cylinder mounting and orientation. It offers flexible mounting options, articulating capability, rotational movement, and adaptable hydraulic connections. These features enable the cylinder to accommodate different equipment configurations, orientations, and working conditions, ensuring optimal performance and load handling.

It’s important to consult the manufacturer’s guidelines and specifications for the boom cylinder to ensure proper installation, alignment, and operation in accordance with the specific equipment and application requirements.

What is a boom cylinder and how does it function in heavy machinery?

A boom cylinder is a hydraulic component used in heavy machinery, such as excavators, cranes, and loaders. It plays a crucial role in extending, retracting, and controlling the movement of the boom, which is the large arm-like structure on the machinery. Here’s a detailed explanation of its function:

- Boom Extension and Retraction: The boom cylinder enables the extension and retraction of the boom. By extending the cylinder, hydraulic pressure is applied, causing the boom to extend outward. Conversely, retracting the cylinder allows the boom to retract back to its original position. This controlled movement of the boom provides reach and versatility to heavy machinery, allowing them to access different areas or work at varying distances.

- Boom Lifting and Lowering: In addition to extension and retraction, the boom cylinder also facilitates the lifting and lowering of the boom. By adjusting the hydraulic pressure within the cylinder, operators can control the vertical movement of the boom. This functionality is essential for tasks that require raising or lowering heavy loads, such as lifting materials, excavating, or placing objects at different heights.

- Load Control: The boom cylinder contributes to load control during heavy machinery operations. By adjusting the extension, retraction, lifting, or lowering of the boom, operators can precisely position the load or equipment. This control over the boom movement ensures safe and accurate load handling, preventing sudden shifts or imbalances that could lead to accidents or damage.

- Hydraulic Power Transmission: The boom cylinder utilizes hydraulic power to generate the required force for boom movement. Hydraulic fluid under pressure is supplied to the cylinder, exerting force on the piston inside. This force is then transferred to the boom, enabling its extension, retraction, lifting, or lowering. The hydraulic system’s ability to transmit power efficiently allows for smooth and controlled boom operation.

- Integration with Control Systems: Boom cylinders can be integrated into control systems or hydraulic circuits of heavy machinery. This integration enables automated and synchronized boom movements, enhancing operational efficiency and precision. Operators can control the boom cylinder using control panels, joysticks, or other control mechanisms, allowing for seamless coordination with other machine functions.

- Strength and Durability: Boom cylinders are designed to withstand heavy loads, harsh operating conditions, and repetitive movements. They are constructed with robust materials, such as high-strength steel, and undergo rigorous testing to ensure durability and reliability. The strength and durability of boom cylinders enable them to handle demanding tasks in heavy machinery applications.

In summary, a boom cylinder is a hydraulic component that extends, retracts, and controls the movement of the boom in heavy machinery. Its functions include boom extension and retraction, boom lifting and lowering, load control, hydraulic power transmission, integration with control systems, and providing strength and durability. The boom cylinder’s role is critical in enabling the efficient and precise operation of heavy machinery, enhancing productivity and safety in various industries.

editor by CX 2024-04-10