Product Description

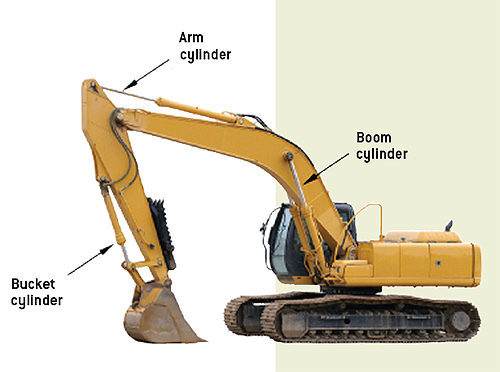

EXCAVATOR HYDRAULIC CYLINDER

ARM CYLINDER, BOOM CYLINDER , BUCKET CYLINDER

KOM ATSU: PC35MR ,PC55, PC60,PC75, PC78, PC120,PC128, PC130, PC200, PC220, PC300, PC360, PC400, PC450, PC650, PC1200,

CATERPILLAR: CAT 312, 350

Hitachi: EX100, EX120, EX150, EX160, EX200, EX220, EX300, EX400, ZX200,ZX210,ZX330,ZX400

Daewoo: DH55,DH200, DH220, DH280, DH300, DH320, DH330,DH420

Hyundai: R200, R210, R220, R225,R250, R290,R305,R335, R360, R400, R500

Volvo: EC210.EC240, EC290, EC360, EC460

Sumitomo: SH60, SH100, SH120, SH200, SH220, SH300, LS580, LS1600, LS2600, LS2650, LS2800, LS3400, LS4300

Mitsubishi: MS180, MS230, MS240, MS380

KATO: HD250, HD400, HD450, HD510, HD550, HD650, HD700, HD770, HD800, HD820, HD850, HD880, HD900, HD1200, HD1250, HD1430, HD1880

KOBELCO: SK07, SK60, SK100, SK120, SK200, SK220, SK230, SK300, SK09, SK912, SK907

SHXIHU (WEST LAKE) DIS.I: SE60 SE70 SE80 SE130 SE210, SE220, SE240 ,SE270 SE330 SE360

ZOOMLION: ZE60 ZE85 ZE210 ZE220 ZE230 ZE260 ZE330 ZE360 ZE480 ZE700

xugong: XE15 XE40 XE50 XE135 XE150 XE210 XE230 XE235 XE260 XE335 XE370 XE390 XE470 XE490 XE500 XE700

SANY: SY55, SY60,SY65,SY75,SY85, SY95,SY115, SY135, SY155,SY205, SY215,SY225,SY235,SY265,SY305,SY335,SY365,SY385, SY465 SY700, SY850

XIHU (WEST LAKE) DIS.DE: SC760, SC485, SC450, SC400, SC360, SC300, SC330, SC270, SC240, SC220 , SC210

LIUGONG: CLG908, CLG909, CLG920, CLG922, CLG925, CLG927, CLG933, CLG936, CLG939, CLG945,

LONGKING: LG6150 LG6215 CDM6150 CDM6210 CDM6225 CDM6235

| 707-01-XY800 |

| 707-01-XY810 |

| 707-01-XY820 |

| 707-01-XZ901 |

| 707-01-XY442 |

| 707-01-XY452 |

| 707-01-0H091 |

| 707-01-0A430 |

| 707-01-0A450 |

| 707-01-0A460 |

| 707-01-XZ993 |

| 707-01-XU760/770 |

| 707-01-XU780 |

| 707-01-XU790 |

| 208-63-57130 |

| 208-63-57120 |

| 707-01-0H081 |

| 707-01-0H061 |

| 707-01-0H091 |

| 207-63-57130 |

| Warranty: | 12 Month |

|---|---|

| Type: | Cylinder |

| Application: | Excavator |

| Certification: | ISO9001: 2000 |

| Condition: | New |

| Transport Package: | Pallet |

| Customization: |

Available

|

|

|---|

How does a boom cylinder contribute to energy-efficient equipment operation?

A boom cylinder plays a significant role in achieving energy-efficient equipment operation. Here’s a detailed explanation:

Energy efficiency is a crucial consideration in modern equipment design, as it helps reduce operating costs, minimize environmental impact, and optimize performance. Boom cylinders contribute to energy-efficient equipment operation in several ways:

- Optimized Hydraulic System: Boom cylinders are part of a hydraulic system that operates the equipment. By designing the hydraulic system to match the load requirements and minimize pressure losses, boom cylinders can contribute to energy efficiency. Proper sizing of hydraulic components, including the cylinder, pump, and valves, ensures that the system operates at optimal efficiency, reducing energy waste.

- Variable Force Control: Boom cylinders offer variable force control, allowing operators to match the force exerted during lifting and lowering operations to the specific load requirements. By adjusting the force to the minimum necessary level, energy consumption is reduced, resulting in more efficient equipment operation.

- Reduced Friction and Leakage: Boom cylinders are designed to minimize friction and prevent leakage. Friction can cause energy loss within the system, while leakage leads to a loss of hydraulic fluid and subsequent energy waste. By incorporating high-quality seals, precision manufacturing, and effective lubrication, boom cylinders help reduce friction and prevent leakage, maximizing the overall energy efficiency of the equipment.

- Controlled Movement: Boom cylinders enable precise and controlled movement during lifting and lowering operations. This controlled movement minimizes unnecessary acceleration, deceleration, and jerky motions that can lead to energy waste. Smooth and controlled movement provided by the boom cylinder ensures that energy is efficiently utilized to perform the required tasks.

- Integration with Energy Recovery Systems: In some equipment designs, boom cylinders can be integrated with energy recovery systems. These systems capture and store energy that would otherwise be dissipated as heat or wasted during deceleration or load lowering. By recovering and reusing this energy, equipment operation becomes more energy-efficient and sustainable.

By optimizing the hydraulic system, providing variable force control, minimizing friction and leakage, enabling controlled movement, and integrating with energy recovery systems, boom cylinders significantly contribute to energy-efficient equipment operation. These features help reduce energy consumption, improve overall efficiency, and promote sustainable practices in various industries.

It’s important to note that the energy efficiency of equipment operation is influenced by various factors beyond the boom cylinder alone. Proper equipment maintenance, operator training, and system design considerations also play crucial roles in achieving optimal energy efficiency.

Can boom cylinders be used in forestry equipment for tree handling?

Yes, boom cylinders can be used in forestry equipment for tree handling. Here’s a detailed explanation:

Forestry equipment is specifically designed for various tasks related to the harvesting, processing, and transportation of trees and timber. Boom cylinders play a crucial role in tree handling within forestry equipment. Here’s how boom cylinders are utilized in this context:

- Tree Felling: Boom cylinders are used in tree felling equipment, such as feller-bunchers or harvesters. They provide the necessary hydraulic force to control the cutting head or cutting arm, allowing operators to fell trees with precision and control. Boom cylinders enable smooth and controlled movement during the tree felling process.

- Tree Loading and Unloading: In forestry equipment used for log loading and unloading, such as log loaders or skidders, boom cylinders are employed to handle the trees. They enable the lifting, lowering, and positioning of logs or tree stems for loading onto trucks or transporting within the logging site. Boom cylinders provide the necessary force and controlled movement for efficient tree handling.

- Tree Processing: Forestry equipment used for tree processing, such as delimbers or debarkers, utilize boom cylinders to manipulate the trees during the processing operations. Boom cylinders facilitate the controlled movement, positioning, and rotation of the trees, allowing for efficient and precise processing.

- Attachment Control: Boom cylinders are also used to control various attachments in forestry equipment. For example, grapples or clamps used for tree handling can be actuated by boom cylinders. This enables secure gripping, lifting, and manipulation of trees, enhancing the efficiency and safety of tree handling operations.

The use of boom cylinders in forestry equipment for tree handling offers several benefits:

- Precise Control: Boom cylinders provide operators with precise control over the movement and positioning of trees. This precision allows for accurate felling, loading, unloading, and processing of trees, minimizing waste and optimizing productivity.

- Efficient Tree Handling: Boom cylinders enable efficient tree handling by providing the necessary force to lift and manipulate trees of various sizes and weights. The controlled movement and positioning facilitated by boom cylinders streamline the workflow and reduce manual effort, improving overall productivity.

- Operator Safety: Boom cylinders contribute to operator safety during tree handling operations. The controlled movement and stability provided by boom cylinders minimize the risk of accidents or injuries caused by uncontrolled tree movement or sudden shifts in load.

- Adaptability: Boom cylinders can be customized to match the specific requirements of different forestry equipment and tree handling tasks. This adaptability allows for versatility in tree handling, accommodating various tree species, sizes, and terrain conditions.

Overall, boom cylinders are valuable components in forestry equipment for tree handling. They enable precise control, efficient tree manipulation, operator safety, and adaptability to various tree handling tasks in the forestry industry.

It’s important to consult the equipment manufacturer’s guidelines and recommendations to ensure the proper selection, installation, and maintenance of boom cylinders in forestry equipment.

What is a boom cylinder and how does it function in heavy machinery?

A boom cylinder is a hydraulic component used in heavy machinery, such as excavators, cranes, and loaders. It plays a crucial role in extending, retracting, and controlling the movement of the boom, which is the large arm-like structure on the machinery. Here’s a detailed explanation of its function:

- Boom Extension and Retraction: The boom cylinder enables the extension and retraction of the boom. By extending the cylinder, hydraulic pressure is applied, causing the boom to extend outward. Conversely, retracting the cylinder allows the boom to retract back to its original position. This controlled movement of the boom provides reach and versatility to heavy machinery, allowing them to access different areas or work at varying distances.

- Boom Lifting and Lowering: In addition to extension and retraction, the boom cylinder also facilitates the lifting and lowering of the boom. By adjusting the hydraulic pressure within the cylinder, operators can control the vertical movement of the boom. This functionality is essential for tasks that require raising or lowering heavy loads, such as lifting materials, excavating, or placing objects at different heights.

- Load Control: The boom cylinder contributes to load control during heavy machinery operations. By adjusting the extension, retraction, lifting, or lowering of the boom, operators can precisely position the load or equipment. This control over the boom movement ensures safe and accurate load handling, preventing sudden shifts or imbalances that could lead to accidents or damage.

- Hydraulic Power Transmission: The boom cylinder utilizes hydraulic power to generate the required force for boom movement. Hydraulic fluid under pressure is supplied to the cylinder, exerting force on the piston inside. This force is then transferred to the boom, enabling its extension, retraction, lifting, or lowering. The hydraulic system’s ability to transmit power efficiently allows for smooth and controlled boom operation.

- Integration with Control Systems: Boom cylinders can be integrated into control systems or hydraulic circuits of heavy machinery. This integration enables automated and synchronized boom movements, enhancing operational efficiency and precision. Operators can control the boom cylinder using control panels, joysticks, or other control mechanisms, allowing for seamless coordination with other machine functions.

- Strength and Durability: Boom cylinders are designed to withstand heavy loads, harsh operating conditions, and repetitive movements. They are constructed with robust materials, such as high-strength steel, and undergo rigorous testing to ensure durability and reliability. The strength and durability of boom cylinders enable them to handle demanding tasks in heavy machinery applications.

In summary, a boom cylinder is a hydraulic component that extends, retracts, and controls the movement of the boom in heavy machinery. Its functions include boom extension and retraction, boom lifting and lowering, load control, hydraulic power transmission, integration with control systems, and providing strength and durability. The boom cylinder’s role is critical in enabling the efficient and precise operation of heavy machinery, enhancing productivity and safety in various industries.

editor by CX 2023-11-07